“Welding Safety Checklist: Are You Prepared?”

Welding is an essential skill in various industries, from construction to manufacturing. However, it comes with its own set of risks and hazards. That's why having a comprehensive welding safety checklist is crucial for anyone involved in welding activities. This article will guide you through the necessary steps and considerations to ensure you are fully prepared for safe welding practices.

Welding Safety Checklist: Are You Prepared?

Getting started on your welding journey? Before you even pick up your torch, it’s vital to ensure you're prepared with a solid safety checklist. Not only does this checklist protect you, but it also safeguards those around you. Whether you're into MIG welding, TIG welding, or any other method like Arc or Plasma welding, understanding safety protocols is key.

Understanding the Risks Involved in Welding

Welding isn’t just about joining metals; it's about doing so safely and efficiently. The risks can include:

- Burns from hot metal

- Electric shock

- Exposure to harmful fumes

- Eye injuries

- Fire hazards

These risks highlight the importance of being prepared with a robust safety checklist before starting any welding project.

The Importance of Personal Protective Equipment (PPE)

Before diving into specific safety checks, let’s talk about personal protective equipment (PPE). Wearing the right gear can make all the difference when it comes to protecting yourself during the welding process.

Essential PPE for Welders

Welding Helmet

A good quality helmet protects your eyes from harmful UV rays and sparks.

Gloves

Leather gloves offer heat resistance and dexterity for handling materials.

Protective Clothing

Flame-resistant clothing should cover your arms and legs entirely.

Safety Boots

Steel-toed boots protect against heavy falling objects.

Respirators

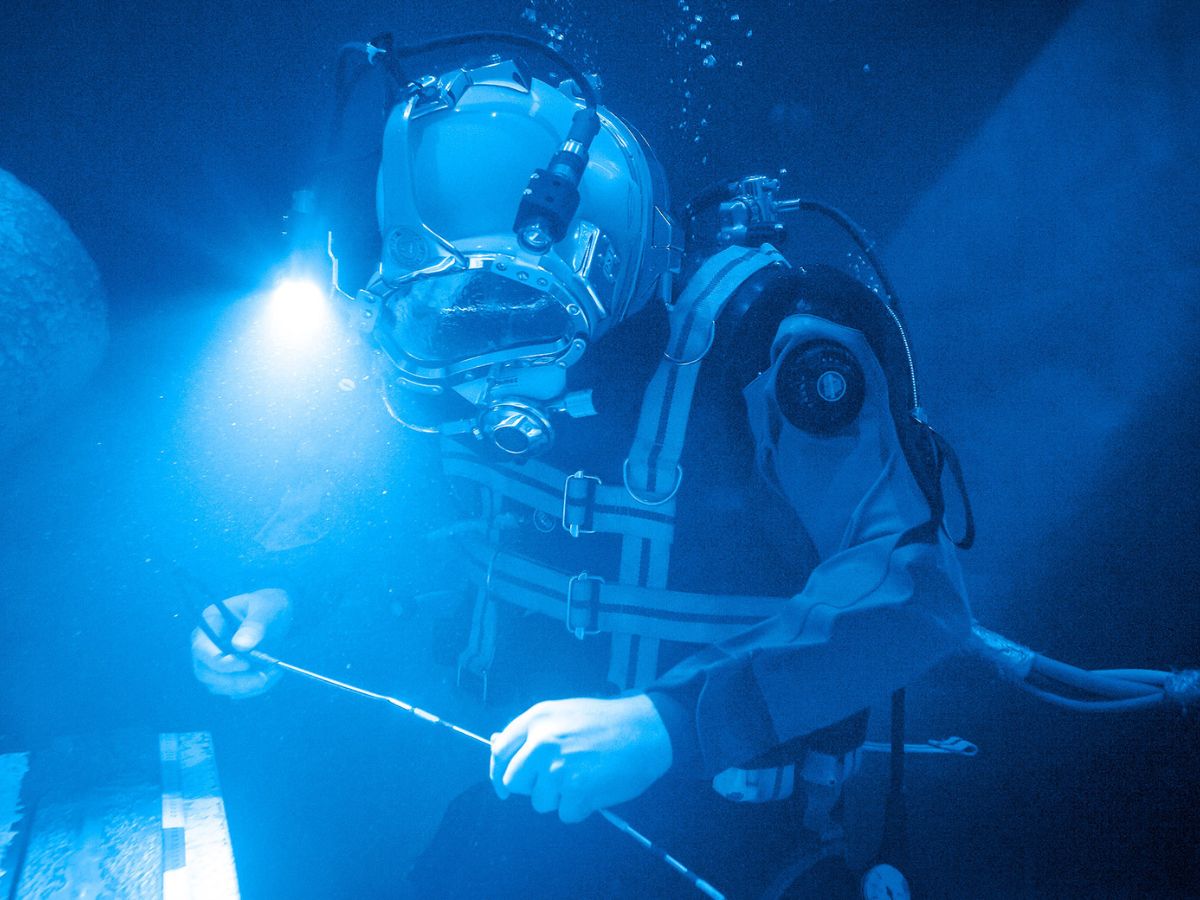

Especially important if you're working in confined spaces or using chemicals during metal fabrication services.

Creating a Safe Work Environment

A well-organized workspace is crucial for safe welding practices. Consider these points:

Work Area Setup

By organizing your space, you're already taking significant steps towards ensuring safety.

Inspecting Your Welding Equipment

Regular inspections of your welding equipment can prevent mishaps before they occur.

Key Equipment Checks

Keeping your equipment in top shape not only enhances performance but also minimizes risks associated with faulty machinery.

Understanding Different Welding Techniques: Their Safety Concerns

Different types of welding have unique hazards associated with them:

MIG Welding Safety Concerns

- Fume exposure due to the melting wire.

- Potential electric shock if equipment is improperly grounded.

TIG Welding Safety Concerns

- High temperatures leading to burns.

- More intricate setups can cause confusion if not well organized.

Arc Welding Safety Concerns

- Intense light that can burn skin and eyes if proper shielding isn't used.

Plasma Welding Safety Concerns

- High voltage can be dangerous without proper precautions.

- Metal particles generated during cutting can become airborne hazards.

Understanding these nuances ensures you're better prepared regardless of the technique you're using.

Welding Ventilation Systems: Why They Matter

Good ventilation is non-negotiable in welding environments as it helps disperse toxic fumes produced during different processes like MIG or TIG welding.

Ventilation Options

Choosing the right ventilation strategy not only protects you but also contributes to overall workplace safety standards.

Emergency Procedures: What You Need To Know

What happens in an emergency situation? Knowing how to react could save lives!

Essential Emergency Protocols

Taking these measures prepares both you and your team for unforeseen events that may arise while working.

Regular Training: Keeping Skills Fresh

Training isn't a one-time event; it should be ongoing! Regular training sessions help keep skills sharp and reinforce safety protocols among welders—especially when new technologies emerge or methods change over time.

Hazard Communication: Understanding Material Safety Data Sheets (MSDS)

Familiarize yourself with MSDS relevant to materials used in your projects—particularly when undertaking mobile welding services in Phoenix or elsewhere where regulations may vary widely!

Key Points About MSDS:

FAQs on Welding Safety

Here are some frequently asked questions about welding safety:

1. What should I wear while welding?

You should wear flame-resistant clothing, gloves, a proper helmet, goggles, and steel-toed boots at all times during the process.

2. How often should I inspect my equipment?

It's advisable to inspect your equipment daily before use as part of standard operating procedures.

3. Is ventilation necessary when using MIG or TIG welders?

Absolutely! Good ventilation prevents accumulation of dangerous fumes produced during these processes.

4. What kinds of fires are most common during welding?

Metal fires caused by molten slag or hot metal are common; hence keeping a Class D fire extinguisher handy is critical!

5. Can I use regular masks while welding?

No! Regular masks do not provide adequate protection against harmful fumes; opt for specialized respirators instead.

6. How do I handle an electrical shock incident?

Immediately shut off power supply if safe; then seek medical attention promptly—even minor shocks warrant evaluation!

Conclusion

Adhering strictly to a comprehensive "Welding Safety Checklist: Are You Prepared?" ensures that every welder—from novices learning MIG & TIG techniques to seasoned professionals engaged in mobile welding services—understands their responsibilities toward personal and collective safety at work sites across Phoenix and beyond! Every step taken today will lead us closer toward creating safer environments where skilled trades thrive securely—a win-win situation all around!

By following this guide on safety checklists tailored specifically for various types of welders—and emphasizing continuous education—we pave pathways towards safer practices while maximizing productivity without compromising on health standards essential within our industry!